Engineering

Everything from the initial idea to development and the final product

Thanks to our involvement in many projects in the machine, apparatus, and equipment manufacturing sectors, we possess the necessary tools required to develop and produce machines for a broad range of applications. encom is well equipped to develop and construct complete machines or to be responsible for sub-projects. We can also support our customers on-site. In addition to developing projects in the laboratory technology, medical technology, and printing and packaging sectors, we can realize and support many different types of project in other sectors.

Ideas

Development

Purchasing

Production

Completion

Development / Manufacturing

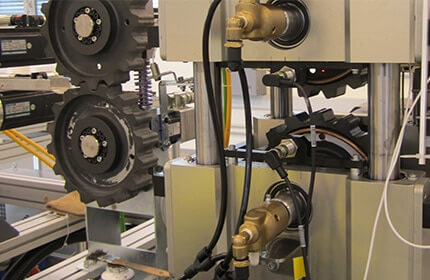

As we were originally a pure service provider in the machine engineering sector, part of our core competency is anything from developing simple devices to complex machines.

Our qualities include efficiency and flexibility. Our customer requirements are at the core of our business and we support them on a daily basis. Our philosophy is to bring a project to market as quickly as possible, with maximum efficiency, and with the highest possible level of quality.

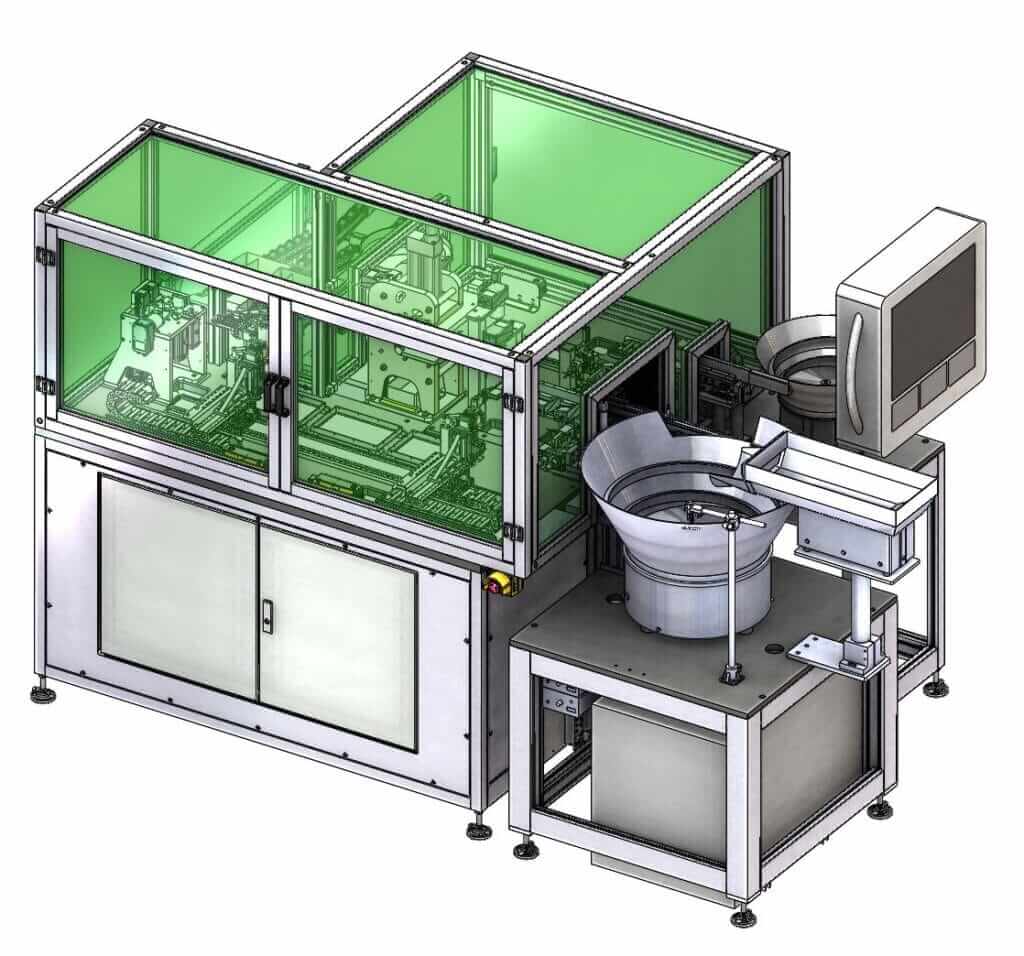

Special-purpose machinery and equipment-manufacturing

Based on the requirements of our customers, we can manufacture special-purpose machinery and equipment individually or in small batches. Thanks to our many years of experience in different industry sectors, we can deliver individual, high-quality solutions.

From developing, assembling, automating, and developing software to installing on-site, encom can cover the entire manufacturing of special-purpose machinery and equipment and thereby guarantee its customers an efficient implementation of projects.

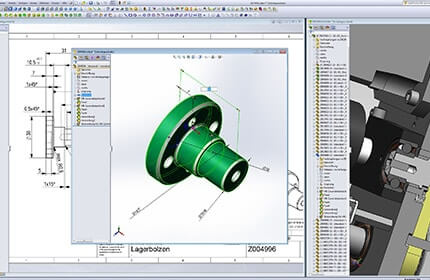

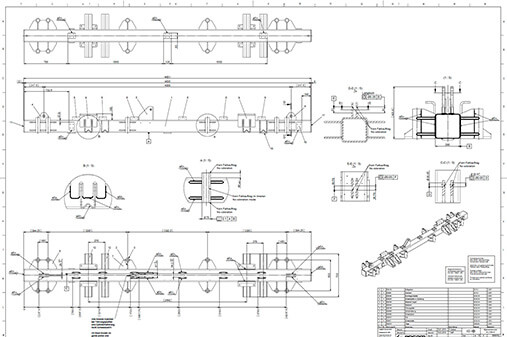

Detail drawings

For engineering projects, only highly qualified employees involved in the relevant project are allowed to generate the detail drawings. On request, we can also commission cost-effective detail drawings from overseas.

However, we only recommend this option when all the main components are clearly defined and finalised. Our partner in the Czech Republic employs highly trained design engineers. In order to ensure encom standards, we check and release all the designs.

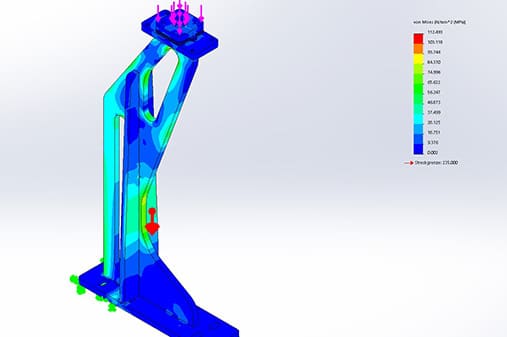

Calculations / Finite Element Analysis (FEA)

encom has highly qualified mechanical engineers. This allows us to complete difficult calculations and FEAs for development projects independently.

For highly complex FEAs, as in the thermal power industry, we have trusted external partners. We also offer pure FEAs, but mainly apply our FEA knowledge in complete development projects.

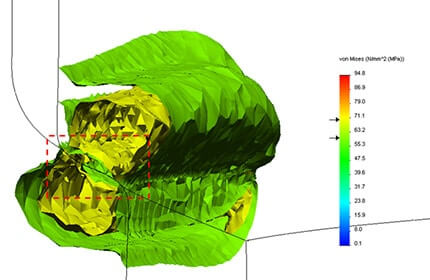

Developing injection-moulding parts and plastics FEA

State-of-the-art plastics are being increasingly used. The range of applications is expansive and the stress analysis is challenging. In short, this is an area that requires a high degree of understanding. encom has developed various products, for example, implants, labware and carriers, and mechanical parts, such as clamping levers, sliding blocks, and panel sheeting.

The manufacturing of these tools is expensive. The parts therefore need to be optimally constructed, in order to minimise the extent of tool modification. We have the necessary knowledge and tools to develop such parts. Our particular competence is that we offer FEAs for materials with non-linear behaviour. In addition, we closely cooperate with specialists from the rapid prototyping, prototyping injection moulding, and series injection moulding production fields.