Winders

Unwinders and rewinders

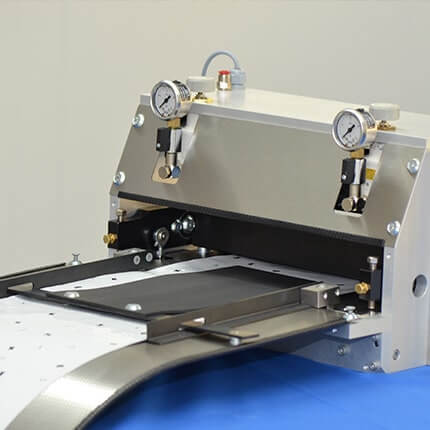

encom has developed its own system that allows winding at speeds of up to 150 metres per minute without a rider roll. The system continually maintains the tension control. The control parameters allow for the processing of many different materials, without the need to adjust the hardware. Even for systems that use mostly the same materials, the mechanically simple system is attractive. The handling is simple and the maintenance is minimal.

Simple and constant

If an average printer quality is required, then the tension is regulated simply with encom’s own servo-powered unwind and rewind system, by means of a load cell and an NIP drive. Thanks to the smart regulating system, a constant tension can be reached. The system saves space and is cost-effective.

For the highest standards

If a high printer quality is required, NIP drives (drum pressure control rolls) are added in front of and behind the printing area, and together they ensure precise tension, which is also suitable for elastic materials. Unwinders and rewinders ensure constant tension in front of and behind the printing area. This allows for processes such as line guiding and coating to be conducted outside the printer. There is also the option of communicating with additional load cells, in order to process materials that are very elastic or difficult to handle.

Standard range

| Type | Max. diameter | Max. width | Max. load | ||||

| UNW 350 | 1016 mm | 350 mm | 500 kg | ||||

| REW 350 | 1016 mm | 350 mm | 500 kg | ||||

Advantages

- Choice of equipment, based on your requirements

- Professional equipment allows for special set-ups without mechanical adjustment

- Pre-clamping spigot for optimal concentricity

- Mounting option for printing pre-treatment

- Options for print pre-treatment available

- Intermediate module for print post-processing available

- Casing can be tailored according to your printer design

- High-quality workmanship

Options

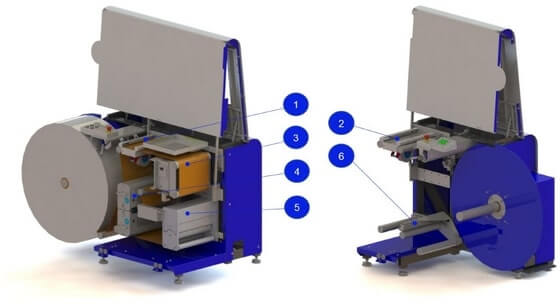

The winders are constructed in such a way that, with the respective adapters, diverse options can be added. The following options can be ordered and other devices can be integrated, on request:

| Pos. | Function | ||

| 1 | Cutting Table | ||

| 2 | Cutting Table | ||

| 3 | Web Guide | ||

| 4 | Cleaner | ||

| 5 | Corona | ||

| 6 | Anti-Static |

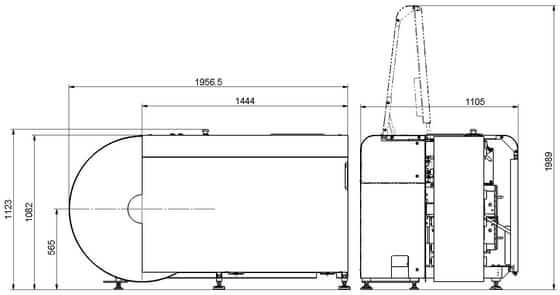

UNW 350 dimensions

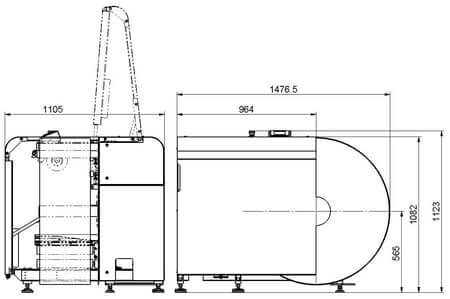

REW 350 dimensions

Additional products

THE RHA reel handling unit

The RHA reel handing unit was designed to transport and place paper reels.

The FTR roll feeding unit

The FTR roll feeding unit was designed to gradually transport almost every type of material.